The following Frequently Asked Question list was submitted to NIT by city hall in Mason City:

Q. How long has Mason City been working on this project?

A. North Iowa Corridor EDC was first contacted about this project by the Iowa Economic Development Authority on December 17, 2015. City and EDC officials met with Prestage leaders on December 18. Two council members were briefed on the initial meeting that day, and the full council was presented with project details in Mid-January, when they offered support to continue discussions.

Q. What is the incentive package being offered by the City?

A. The City is offering a 10-year 50% tax rebate on a $100 million minimum valuation. The rebate is contingent on the company meeting all requirements in the Development Agreement, and subject to annual approval by the City Council. The estimated annual rebate is $1,395,000, while the taxing bodies will bring in $1,771,896 annually. This is all money the City would not have without this project and helps the company through the startup and construction phases when they have no return on their $240 million investment. After 10 years, the governmental entities will receive the full $3,166,896:

- Mason City Public Schools = $1,255,500

- City of Mason City = $1,216,500

- Cerro Gordo County = $562,500

- NIACC = $64,400

- Assessor = $56,900

- Ag Extension = $10,800

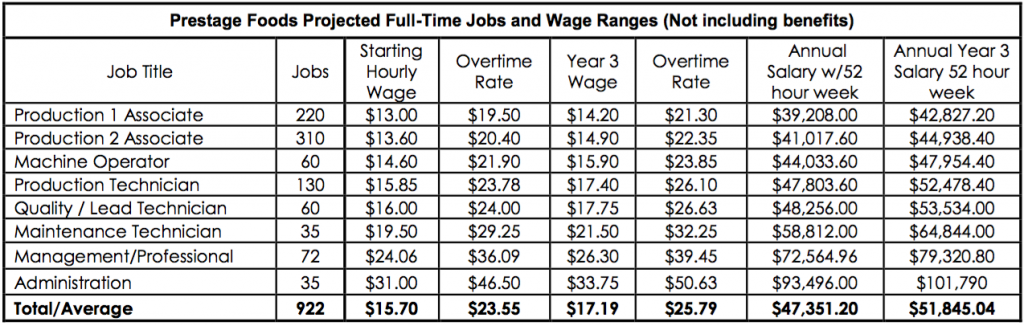

Q. What jobs will be created and how do they pay?

A. The Development Agreement requires Prestage Foods to create 922 full-time jobs averaging $15.70/hr base pay (not including overtime) plus full benefits. Projected total annual payroll is over $43 million with overtime. The plant will operate Monday-Friday with approximately 10 hour shifts. State–of-the-art process systems, robotic equipment, and ergonomically designed work stations greatly reduce manual labor and require a more skilled workforce. Pay ranges below are the minimum required pay levels for each skillset. Prestage will regularly evaluate pay to ensure they get and keep good people. The lowest paid employees are expected to make $39,208/yr, the most recent Iowa Works data from Q3 2015 show the average in Cerro Gordo County to be $39,936. The expected turnover rate is ~25 %, which is in line with employers in the region and industry.

Q. What is the employee benefits package?

A. All 922 full-time employees receive full benefits, with an annual total value to employees of $12,236,722 including:

- Family healthcare with 83% company paid ($811/month value)

- Disability insurance after one year of employment

- Contributions to Health Savings Account

- Paid time off including Vacation, holidays, etc.

- Company paid life insurance

- 401k match

Q. How will this project impact air quality?

A. Areas that have potential to emit odors the livestock barn, rendering, and wastewater pre-treatment] will be appropriately enclosed and utilize intervention technologies to mitigate odor. Wastewater treatment and rendering will use the latest technology available for further remediation and conditioning prior to emission. The holding pond for wastewater treatment will be covered, and the methane captured will be utilized as an energy source.

The City further studied the issue through discussions and research with communities with modern designed plants. Each indicated that odor has not been an issue of significance, even where plants are near neighborhoods. This plant will be more advanced than any in the world, and is also over a mile from the nearest residential neighborhoods in MC. The company will also create an earthen berm along the north of the property, and utilize vegetative buffers to further reduce potential concerns.

Q. How will this facility impact the water supply?

A. The City contracted with Stanley Consultants on January 19, 2016 to prepare a Water System Capacity Evaluation report. The current system capacity is over 9 million gallons per day, but average use is about 4.5 mg/d with a peak of 7 mg/d. The facility will use 1.4 mg/d, which the DNR has confirmed will not take the Jordan Aquifer below regulated levels, or the project could not be approved.

DNR geologists performed analysis on the aquifer based on Mason City and surrounding wells. Following modeling of the Jordan draw down in the Mason City area, he stated in an email, “with proper well placement the city should be fine for decades to come.” Adding new wells to the Jordan will not be an issue with careful planning. The IDNR will continue to advise and assist as we move forward.

Within the Water System Capacity Evaluation report are four options for improvement projects. These are identified in categories such as Water Supply, Water Treatment, Water Storage, Water Transmission Mains, and Water Reclaim. Additional modeling and evaluation is being done to assure the most effective combination of these components are utilized. The City is very well positioned to accommodate not only the Prestage Foods project but also future community development.

Q. How will this facility impact the area’s water quality?

A. The City has worked closely with the DNR and company engineers to determine waste flows from the plant. The company will pre-treat all water leaving the facility and it will enter the City system meeting the same standards as every industry, nothing is released into the area watershed. Testing is required daily to meet local and state regulations. The initial discharge of 1.4 mg/d will be covered by a pre-treatment agreement and is well within the capacity of the City system, which has over 7mg/d excess capacity even on peak flow days. The increased flow will actually improve efficiency in the system.

Q. Will this facility lead to large growth in hog confinement facilities around North Iowa?

A. The plant will harvest 10,000 hogs per day when it opens in 2018. The company produces approximately 6,000 hogs per day on its own farms, and estimates they will need 4,000 per day from independent producers. So they will need about 1 million hogs per year from other sources. According to the 2012 United States Department of Agriculture Ag Census, 11.6 million hogs were marketed within 75 miles of Mason City, and almost 26 million within 100 miles. Industry analysts show that the current hog supply has outpaced available packing capacity as older plants have closed, and over the past 30 years hog production has increased by 1-2% annually whether new plants are built or old ones are closed.

Prestage does not currently own or operate any facilities in Cerro Gordo County. At this time, they have plans for about 10 more permitted sites, and none of those are to be located in Cerro Gordo County. Prestage has publicly stated that they have no plans to build in the Clear Lake water shed or interfere with tourism in the Clear Lake community. Prestage has additionally said that they would discourage any independent producers who sell them hogs from building in or around the Clear Lake community. If in the future farms were built, they have given assurances that these sites would be appropriately located according to state law and good common sense as a good neighbor and community partner.

Q. How will the project impact traffic?

A. Prestage Foods has contracted a local firm to conduct traffic studies to determine impacts and propose any necessary road improvements such as turning lanes and traffic signals. The facility will be located at 1883 43rd St, along the Avenue of the Saints, which will keep truck traffic out of town. There will be 50-55 trucks coming into the facility M-F from 3am-3pm. Trucks will enter from the Avenue of the Saints on Eisenhower Avenue up to 43rd St., unload at the facility, be fully washed and sanitized onsite, then exit east to Federal Ave and back to the Avenue of the Saints. All truck staging will be done onsite and off the roads. Employees and visitors will have a separate entrance on the east side of the facility.

Q. How does Prestage’s turnover rate compare to the processing industry average? What plans do you have to reduce your turnover rate?

A. Prestage has never owned a pork processing facility before, so it is difficult to say what the turnover rate will be. Prestage owns a turkey processing facility that had a turnover rate in 2015 of 23.32%. Prestage’s overall turnover rate, across all divisions, is 22.92 %. At a recent public hearing, Dr. Ron Prestage stated, “we struggled initially at the turkey plant, but we have learned a lot of lessons in the 12 years since we took over operations at that facility, and we plan to apply those lessons learned at this plant.”

Prestage is a family-owned, family-operated company that strives to engage employees on a personal level. Top tiered managers in the company average nearly 20 years of experience, with many having more than 25 years with the company. Every year since its own 25th anniversary, the company and the Prestage family have honored employees with 25 years of service. Read more about their celebration of these employees here.

Q: Deckers paid very good wages, but wages not keeping pace with inflation is a serious problem.

A. Prestage’s wages are in line with North Central Iowa manufacturers and food processing companies for each job/skill classification. A competitive benefits package will be offered as well as overtime opportunities to increase earnings potential. The County average income is $39,936, and the lowest paid employees here are projected to make $39,208, while the average is over $47,000, not including benefits. Prestage has always believed in promoting from within and giving employees the opportunity to increase their responsibility and earnings with experience. Prestage recognizes their obligation to be competitive and understands that this helps create a positive workplace culture and lasting job security. A thriving company can increase wages and provide additional opportunities for their employees.

Q. Is overtime mandatory?

A. Once at full capacity, the plant expects to operate on 10 hour shifts. Any time over 40 hours per week will be paid at time and a half.

Q. Where will Prestage get the workers for the plant?

A. In the communities where they operate today, Prestage strives to be an employer of choice, not necessity. They are committed to working tirelessly to prove this in Mason City as well. Prestage will offer a strong benefits package that includes paid time off, 401-k match, company life insurance, and affordable family health insurance. In addition, Prestage expects overtime opportunities that will allow its employees to maximize their weekly earnings potential.

Prestage cannot, nor will they, discriminate; however, Prestage does utilize the tools available to ensure that every employee hired is legal to work in the United States. All employees, regardless of origin, are E- verified, and Prestage has never had a citation or violation regarding employee immigration status.

Q. What radius will pigs be shipped from? 75, 100, 200 miles?

A. Prestage plans to receive hogs at this plant from throughout the Midwest. There is no 75-mile radius limit around the plant for the purpose of procuring hogs. Today, hogs in Iowa travel hundreds of miles to processing facilities and this facility will be no different. It is preferred, for disease purposes, to diversify the geographic locations of the source of animals. That, along with transportation costs and local market conditions, will determine how hogs are sourced for this plant. Farms within 75 miles may have an advantage but will not be the only hogs purchased. There are absolutely no plans to concentrate feeding facilities within the county or a 75 mile radius.

Q. What does Prestage do for humane treatment of animals?

A. Prestage’s Animal Welfare Statement can be read here. Prestage has a zero tolerance policy for any willful acts of abuse. ANY employee, regardless of tenure or position, found to have committed a willful act of abuse or handled any animal in an inhumane manner is terminated immediately.

Q. Does Prestage have any plans to build confinement operations in Cerro Gordo County? What technologies does Prestage use to mitigate the effects of their confinement operations?

A. Prestage currently does not own or operate any facilities in Cerro Gordo County. At present, they have plans for about 10 more permitted sites, and none of those are to be located in Cerro Gordo County. While there are no current plans to build in Cerro Gordo County, if in the future Prestage did build, they have publically committed that these sites would be appropriately located according to state law and good common sense as community partners. Prestage has publicly stated that they have no plans to build in the Clear Lake watershed or negatively impact tourism in Clear Lake or the rest of the County. Prestage has additionally stated that they would discourage any independent producers who sell them hogs from building in or around communities.

Prestage facilities are modern confinement operations that are well maintained and utilize the latest in construction, ventilation, and waste management technologies. Prestage utilizes vegetation buffers around facilities as needed to mitigate sights, sounds, and odors that might cause concern to neighbors. Additionally, pit additives are utilized as needed.

Iowa’s livestock farms are heavily regulated by the Iowa Department of Natural Resources. All confined animal feeding operations are required to follow state regulations when building or operating a facility including being appropriately permitted and maintaining required records. Waste management permits require retaining all manure until it is land applied, observing manure land application separation distances, and reporting manure releases in the event of catastrophic failure. In addition to required zero- discharge permitting, large confinement operations (more than 500 animal unit capacity) must have an approved manure management plan and use a certified manure applicator to apply manure.

Q. Are there other plans to be environmentally responsible? Will any of the byproduct be recaptured or recycled?

A. One of Prestage’s founding principles is to be good environmental stewards. When choosing colors for the company logo, the iconic blue and green were selected to represent “blue skies” and “green grass”. Prestage’s full environmental impact statement can be read here.

This plant will recover heat from the rendering system to supply hot water for the plant, thus reducing energy consumption to heat water. In addition, the plant will invest in a unique scalding system for processing which reduces water consumption for this process by over 50%. Prestage also anticipates a water reuse program which allows the plant to use some water twice in non-potable areas which reduces the overall need for water and wastewater treatment. Finally, the plant will invest in energy efficient lighting and electrical components which both reduce energy consumption and meet Alliant Energy’s program requirements for energy efficiency.

Several water flows will be recycled along with process heat. In addition, methane will be captured and used as energy. Captured methane has the potential to be used in a variety of different ways. Methane, a biogas, could be used in a boiler to displace natural gas usage, it could be combusted to produce green power on-site, or it could be cleaned and put back into the natural gas pipeline to be used by power companies to produce electricity. The most efficient use of this natural resource will be determined as the specifications for the facility are completed.

Q. What advanced technologies will be used to clean air prior to release?

A. Prestage will incorporate modern “air scrubbing” technology designed specifically for the rendering and food processing industry. While the vendor has not yet been contracted, these systems are typically custom designed for anticipated volumes and the specific material that is being processed. One of the premier companies providing this type of equipment today is AC Corporation in Greensboro, NC.

The plant will be constructed to contain odors including enclosing areas subject to odors and creating negative air pressure to reduce air emissions. In addition, process materials subject to odor will be transported through a closed pipe system which reduces exposure to the atmosphere as opposed to more traditional transport methods such as trucks and open conveyors.

Q. What kind of pre-treatment will be done prior to wastewater going back into the city system?

A. The design of this system has not been finalized, but Prestage anticipates a multi-step process including both aerobic and anaerobic treatment steps. Methane will be captured in the anaerobic process as an energy source. The resulting pre-treated water will meet the required BOD and TSS levels required by the city for final treatment at the city’s municipal treatment plant. Prestage Farms will not directly discharge to any public waterway from this facility.

Q. It has been said that Prestage has been “run out” of NC. Is it true that there is a moratorium on hog farming in North Carolina?

A. It is absolutely untrue that Prestage has been “run out” of NC. North Carolina is home to their founding division as well as their company headquarters. Prestage is a well-respected member of the pork, turkey, and business community at large in all of the states in which they operate and has been awarded and recognized at local, state, and national levels

It is true that there is a moratorium in NC, but it is not actually on hog farming or the expansion of the pork industry. The moratorium is actually on a particular waste management technology, the lagoon and spray field system. Under the conditions of the moratorium, new operations can still be built, but they must use an alternative waste management technology which, due to a variety of factors [cost, climate, soil types…etc], has proven impractical.

Q. How did Prestage come to be in Iowa? Why did they decide to build a plant in Mason City and not North Carolina?

A. Prestage Farms is a family-owned, family-operated business that was started by the Prestage family in 1983 as a local pork and poultry producer in North Carolina. While there were no original plans to expand to other states, in 1991, Prestage Farms was approached by Bryan Foods to supply hogs to their plant in West Point, Mississippi. This successful partnership represented the first satellite division. Just three years later, Prestage was approached again; this time to supply turkeys to what was then Louis Rich a division of Kraft Foods, thus establishing Prestage Farms of South Carolina. In the early 2000’s, Prestage saw an opportunity to again expand when another company put their operations up for sale in Iowa, and in 2004, Prestage Farms of Iowa was established. The latest expansion occurred when Prestage purchased a division that was being sold by another company in Oklahoma in 2011. Throughout its history, Prestage’s expansion has been done through sound business decisions while never losing sight of its original mission.

Prestage Farms believes that the consolidation of the pork packing industry has decreased competition for live hogs and helped depress prices to hog producers. As a large family-owned and operated, independent hog producer, Prestage believes that building this plant is the logical next step in protecting its hog production investment. In addition, Prestage wants to create additional opportunities for independent producers in Iowa to maximize value for their livestock. As the largest hog producing state in the nation by a wide margin, Iowa is the logical place to locate Prestage’s first pork processing venture.

Q. Will this negatively impact the quality of life in Mason City?

A. Prestage accepts responsibility for enhancing and growing the quality of life of the communities in which it operates and never wants to be viewed as a detriment. The Prestage family has always sought to connect and engage in a positive way in its communities. For example: by purchasing supplies and services from local sources whenever possible, Prestage wants to contribute to local economies, developing long-term business relationships with neighboring businesses while getting to know business owners and associates and sharing more than just a business transaction over the telephone or by e-mail.

Prestage believes in hiring and developing employees that share their passion for being active participants and contributors to our communities. Via payroll deduction campaigns and individual gifts, the employees of Prestage contribute over $75,000 annually to causes of their choosing. Additionally, as food producers, Prestage is fervent about advancing the future of agriculture and seeks to align financially and through volunteerism with organizations who share this desire.

Prestage Farms seeks to weave itself into a thriving community filled with all the necessary resources for a solid quality of life supporting medical facilities, law enforcement, as well as fire and rescue squads. Prestage recognizes the importance of education at the local level and at institutions of higher learning, and is honored to assist in growing existing as well as new programs to develop youth and adults through tax base, capital donations, and volunteerism.

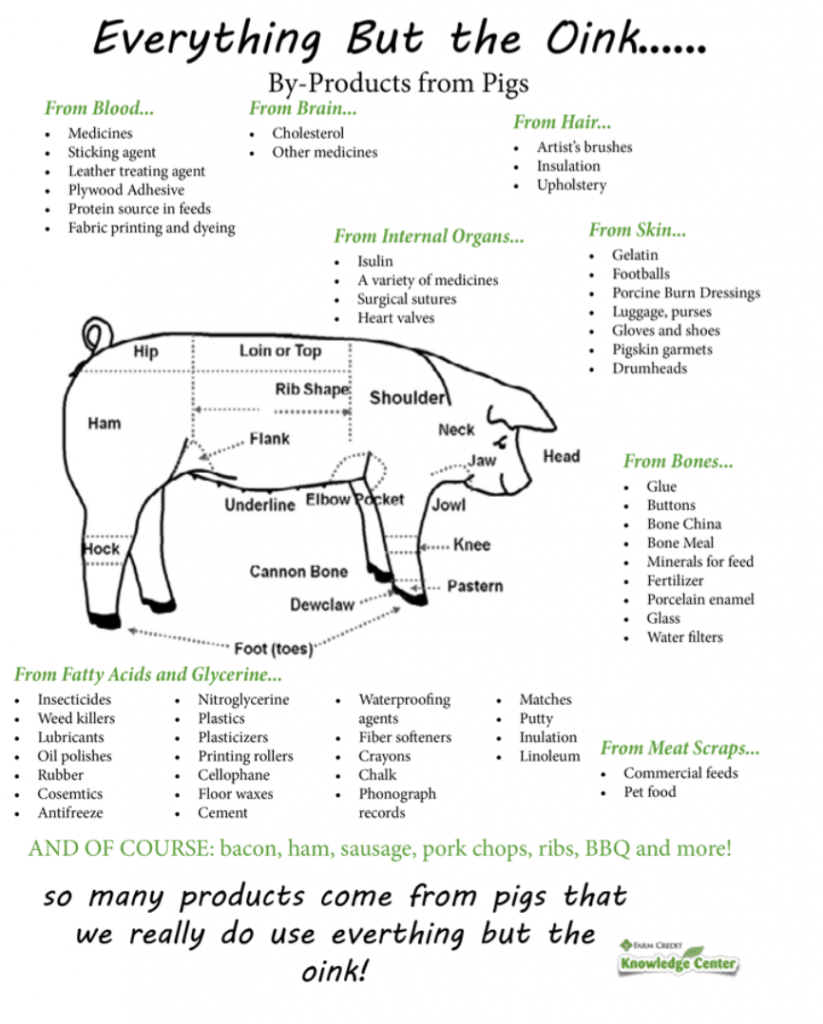

Q. It has been stated that “everything is used but the squeal.” What other products are made from the pig? Is the landfill used at all? If so, for what?

A. Both in production and processing, pork systems are designed to be very efficient recyclers. At the plant, Prestage will have onsite rendering facilities so there will be NO pig byproducts of any kind sent to the landfill. The only materials that will go into the landfill from the plant will be paper trash from the office, product packaging …etc.

Below is an infographic detailing what all of the different parts of the pig are used for: