Modern print shops need solutions that balance speed, accuracy, and consistent quality. UV sticker gang sheet builders help organize multiple designs into a single layout while maintaining precise spacing. This approach allows shops to improve productivity without compromising visual standards.

These tools also support reliable curing and stronger adhesion across all stickers. Better layout control reduces material waste and production errors. As demand grows, print shops can scale operations while keeping output consistent and efficient.

What Is a UV Sticker Gang Sheet Builder

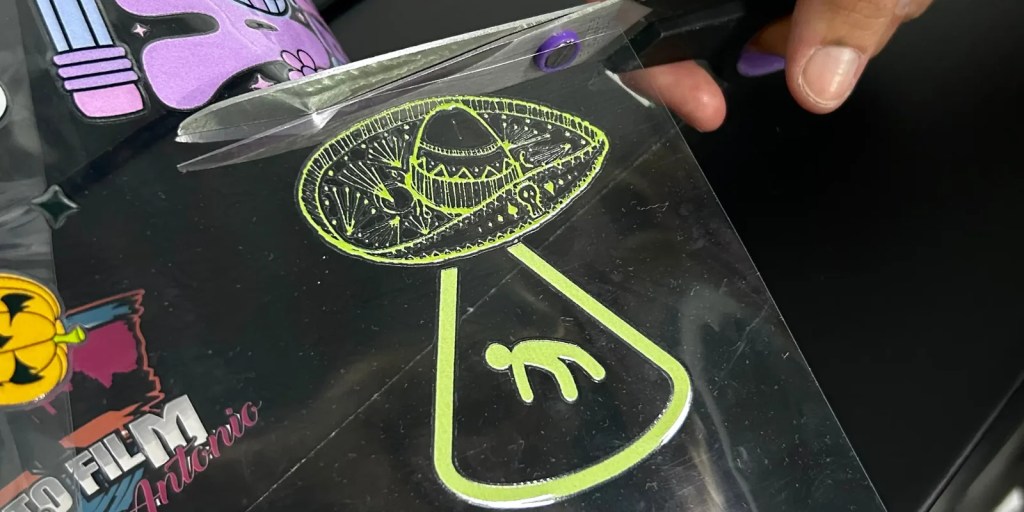

A UV sticker gang sheet builder is a digital tool that allows multiple sticker designs to be arranged and printed on a single UV DTF sheet. This approach helps print shops optimize layout space while maintaining consistent curing and adhesion. Print providers working with trusted production partners like DTF San Antonio benefit from improved workflow efficiency, reduced waste, and professional grade results that meet modern production standards.

- Combines multiple sticker designs into one printable sheet

- Ensures consistent UV curing across all graphics

- Improves layout accuracy and spacing

- Reduces material waste across production runs

- Minimizes setup time for faster output

- Supports both high volume and custom orders

- Enhances overall print consistency

- Improves efficiency across the production workflow

How UV Sticker Gang Sheet Builders Improve Print Operations

UV sticker gang sheet builders streamline production by allowing multiple designs to be printed in a single, well organized layout. This improves accuracy, reduces setup time, and minimizes material waste. As a result, print shops achieve faster turnaround while maintaining consistent, high quality output.

-

Optimized Layout Efficiency

Gang sheet builders allow print shops to make full use of available sheet space. Designs are arranged strategically to minimize empty areas while maintaining proper spacing. This layout optimization directly reduces film and ink usage.

Better layouts also improve cutting and dtf application accuracy. When designs are aligned correctly, post production handling becomes faster and more reliable.

-

Consistent Print Quality Across Designs

Printing multiple stickers in a single run ensures consistent color density and curing. All designs experience the same exposure and print conditions. This eliminates variation that can occur when printing designs individually.

Consistency is especially important for branding and logo based stickers. Uniform appearance reinforces brand credibility and customer trust.

-

Stronger Adhesion and Durability

UV sticker gang sheet builders support precise layering of ink and adhesive. This controlled process improves how stickers bond to surfaces like glass, plastic, metal, and coated materials. Strong adhesion reduces peeling and lifting over time.

Durable stickers perform better in real world conditions. Long lasting products reduce complaints and increase repeat business.

-

Faster Turnaround Times

By combining multiple designs into one sheet, print shops significantly reduce setup and production time. Fewer print runs mean faster order completion. This speed allows shops to handle rush orders and higher volumes efficiently.

Faster turnaround improves customer satisfaction. Meeting deadlines consistently builds strong client relationships.

-

Reduced Production Errors

Manual layout processes increase the risk of alignment issues and spacing errors. Gang sheet builders automate layout precision, reducing human error. This leads to fewer reprints and less wasted material.

Lower error rates save time and money. Print shops can focus on quality control instead of correcting avoidable mistakes.

-

Improved Workflow Management

UV sticker gang sheet builders integrate seamlessly into modern print workflows. They simplify file preparation and standardize production steps, creating a smoother transition from design to print.

Efficient workflows help teams stay organized and reduce bottlenecks. Clear processes improve productivity across departments and support consistent output quality.

-

Scalability for Growing Print Shops

As order volumes increase, gang sheet builders make scaling easier. More designs can be added to each sheet without increasing setup complexity. This allows shops to grow without overhauling their systems.

Scalable production supports long term business growth. Print shops can expand confidently while maintaining quality.

Additional Benefits of Using UV Sticker Gang Sheet Builders

Beyond operational efficiency, gang sheet builders offer strategic advantages that help print shops remain competitive. These tools support cleaner workflows, lower material waste, and more predictable production outcomes.

Print shops that implement a reliable UV Sticker Gang Sheet Builder gain better control over quality, scalability, and long term efficiency.

-

Lower Cost Per Sticker

Printing multiple stickers together reduces material and labor costs per unit. Ink, film, and curing time are shared across designs, lowering overall production expenses.

Cost savings allow print shops to offer competitive pricing. Better margins support sustainable growth and long term business stability.

-

Flexibility for Custom Orders

Gang sheet builders support a mix of sticker sizes and designs on one sheet. This flexibility is ideal for custom and short run orders, allowing efficient production.

Custom capability attracts more clients and strengthens customer satisfaction. Flexibility becomes a key selling point for print shops offering personalized products.

-

Reduced Material Waste

Efficient layout planning minimizes unused film space, resulting in fewer discarded materials and lower disposal costs. This approach supports responsible resource management.

Sustainability is increasingly important to customers and influences buying decisions. Reduced waste also enhances the print shop’s brand reputation.

-

Improved Inventory Control

Producing stickers as needed reduces excess inventory, allowing print shops to manage stock more efficiently and avoid overproduction. This improves cash flow and storage efficiency.

Better inventory control leads to smoother operations and fewer bottlenecks. It also reduces financial risk and supports long term business stability.

-

Enhanced Brand Consistency for Clients

Clients expect their stickers to look the same across every order, and gang sheet builders ensure consistent finish, thickness, and color. This reliability strengthens client trust.

Consistency is critical for professional branding and reflects attention to detail. It also reinforces the perception of quality and professionalism.

-

Better Use of Skilled Labor

Automated layout tools reduce repetitive manual tasks, allowing staff to focus on quality checks, customer service, and creative work. This improves job efficiency and morale.

Skilled labor is used where it adds the most value, making operations more balanced and productive. Teams can contribute to higher quality outcomes and smoother workflows.

How Modern Print Shops Maximize Efficiency with Gang Sheet Workflows

Modern print shops don’t just rely on UV sticker gang sheet builders for better layouts—they use them to transform entire production workflows. By integrating gang sheet planning into daily operations, shops can coordinate multiple departments, from design to finishing, ensuring everyone works efficiently and in sync.

- Streamlined Prepress Operations: Designers and prepress teams can prepare multiple designs in a single workflow, reducing file handling errors and speeding up production. Standardized layouts ensure that printing runs smoothly every time.

- Optimized Production Scheduling: Print managers can combine rush orders with standard runs without sacrificing quality. Gang sheet workflows allow for predictable timing, helping shops meet tight deadlines and handle larger volumes with ease.

- Better Resource Allocation: Labor and materials are used more effectively. Technicians focus on quality control instead of repetitive tasks, and material consumption is reduced, lowering costs and environmental impact.

- Enhanced Client Experience: Faster turnaround, consistent quality, and the ability to handle customized orders help shops impress clients and encourage repeat business. Gang sheet workflows support both high-volume and personalized projects seamlessly.

- Data-Driven Workflow Improvements: By tracking performance metrics for gang sheet usage, print shops can identify bottlenecks and continuously improve their efficiency and output quality. This makes them more competitive in a growing and demanding market.

Key Takeaways for Print Shops

Adopting UV sticker gang sheet builders allows print shops to improve quality, efficiency, and scalability.

- Optimized layouts reduce waste and costs

- Consistent curing improves adhesion and durability

- Faster production supports higher order volumes

- Reduced errors increase profitability

- Scalable workflows support business growth

Midway through production planning, many shops choose to work with a reliable partner offering professional UV DTF gang sheet solutions to ensure consistent results and efficient workflows. Collaborating with an experienced provider helps streamline production while maintaining high quality standards.

Conclusion

UV sticker gang sheet builders help print shops improve efficiency, quality, and scalability while reducing waste and enhancing adhesion. By streamlining workflows, shops can meet growing demand with consistent, durable stickers, faster turnaround, and lower costs.