In industrial settings, durability and efficiency influence decision-making when selecting components for fluid control. Ball valves are the go-to option due to their reliable performance and robust construction. These valves can manage high-pressure and temperature conditions, common in various industrial applications. Their simple operation, combined with a leak-tight seal, makes them suitable for both on-off and throttling services. Keep reading to learn more.

Choosing the Right Manufacturer

When selecting a provider, research manufacturers thoroughly. Quality control measures, industry certifications, and product warranties are indicators of a reliable manufacturer. Companies known for their rigorous testing and adherence to standards offer products that perform in high-stakes environments. Conducting market comparisons can reveal differences in material quality and design features that impact performance and durability. For a steel ball valve manufacturer, look for one that meets operational requirements. To make the right choice, explore feedback from existing clients. Word-of-mouth experiences can provide valuable insights into the reliability and service levels of manufacturers.

Opting for a well-regarded company that provides exceptional customer service can ease any complications during the procurement and installation processes. An investment in a trusted manufacturer leads to a dependable supply chain and consistent product availability.

The Mechanical Advantage of Ball Valves

The mechanical design of ball valves sets them apart from other valve types. They utilize a spherical disc, known as a ball, which pivots to either allow or block fluid flow. The primary advantage of this design lies in its ability to create a tight seal. When the ball is in the closed position, it compresses against the valve seats made from durable materials to minimize the leaking. The rotational movement required to operate these valves offers less friction and wear compared to others.

Unlike other valve types that can create turbulence, ball valves allow for straight-through flow. Their ease of operation adds to their appeal in high-demand industrial processes. For large-scale applications, quick-open and close functions improve operational efficiency and safety in processes that require strict control over fluids.

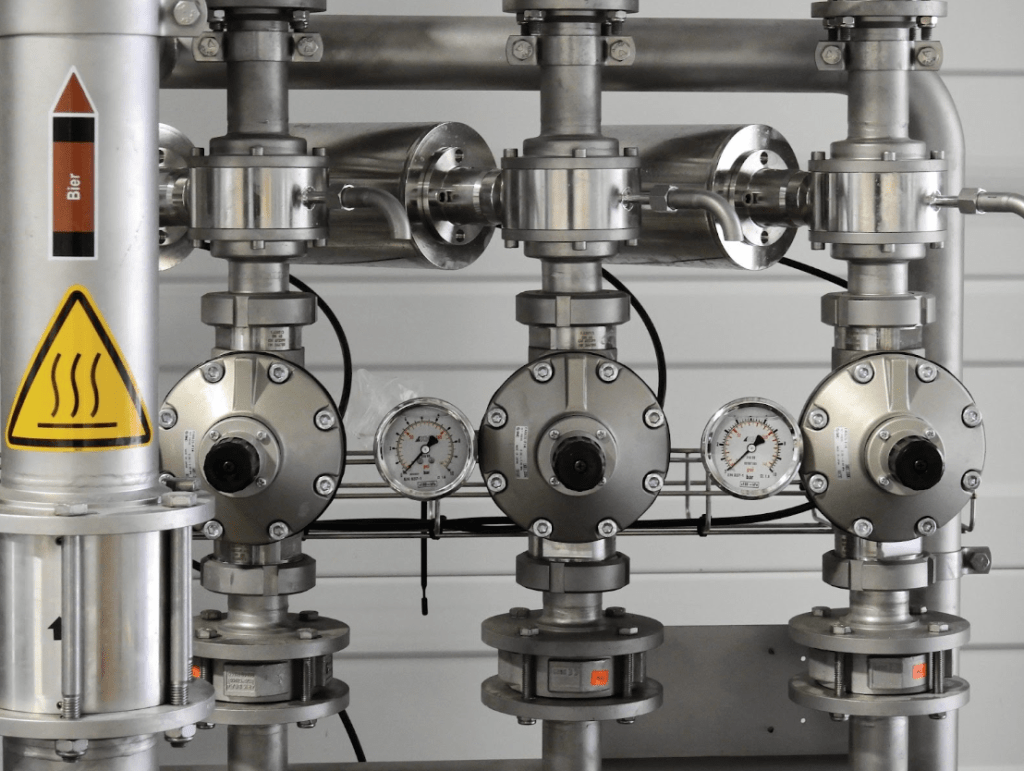

Applications Across Various Industries

Ball valves find extensive use across numerous industries. In the oil and gas sector, they drill operations, pipeline control, and processing systems. This type of valve is favored in high-pressure applications found in this industry, where operational integrity for environmental safety and regulatory compliance is required. The chemical manufacturing industry utilizes ball valves extensively due to their ability to handle corrosive substances.

The food and beverage industry relies on sanitary ball valves for higher hygiene standards. Highlight that ball valves are chosen for applications requiring quick operation, as their design allows for full open positions that lower the time taken to manage fluid flow. Ball valves can be tailored to meet specific operational requirements and make them adaptable across different industrial contexts.

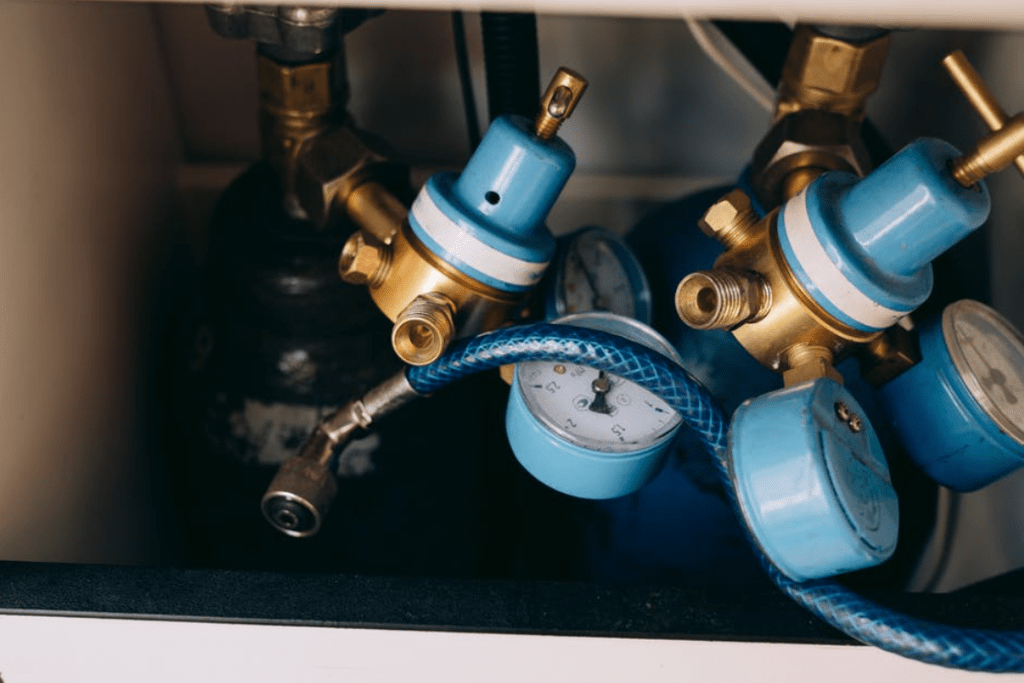

Material Selection

The material used in the construction of ball valves is a determining factor for performance and longevity. Stainless steel and brass are two commonly used materials; the choice between them often depends on the application. Stainless steel ball valves are popular in demanding environments due to their corrosion resistance and ability to withstand extreme temperatures and pressures. These valves are capable of handling most fluids. Brass ball valves are used in less demanding conditions. They may offer longevibut ty, but their performance may not match that of stainless steel under more challenging conditions.

Organizations increasingly adopt modern stainless steel versions for their enhanced durability and efficiency. The introduction of different finishes and coatings improves the performance of these valves in various applications, adding to their versatility.

Installation and Maintenance Considerations

Ball valves are known for their robustness, but that doesn’t mean businesses need to shy away from proper installation and maintenance. Follow manufacturer guidelines closely during installation to avoid misalignment or undue stress on the valve components. Failure to adhere to proper practices can cause premature wear.

Lubrication around the valve stem can improve movement and reduce the risk of seizing or leakage. Training personnel handling these valves on best practices can drastically prolong their life cycle and efficiency. Having a knowledgeable team eases the workload and prevents errors. Scheduling regular training sessions can keep personnel updated with specific techniques and technologies.

Cost-Effectiveness and Energy Efficiency

The initial investment may be higher than less durable options. Know that their longevity and lower maintenance requirements translate into considerable savings. Ball valves contribute to a more energy-efficient system and reduce utility costs. Energy efficiency impacts costs and influences environmental considerations.

With robust designs, ball valves facilitate effective fluid control in a way that reduces waste and promotes reliability. Organizations that prioritize energy-efficient solutions and invest in high-quality components will position themselves for long-term success. The cost-effectiveness of good ball valves can result in sustainable operational practices that benefit business operations and the environment.

Thanks to their reliability, efficiency, and adaptability across applications, ball valves are preferred in industrial environments. The mechanical design, material choices, installation practices, and proper manufacturer selections realize the full potential of these valves. Their long-standing durability and effectiveness solidify their position as components in fluid control systems.